Inaugural Malawi Project 2021

2021 marked a new adventure for African Water, as we stepped outside of Zambia for the very first time and investigated suitable water projects in Malawi, along the border with Zambia. Bright deployed to Malawi on a research project to investigate the suitability of proposed projects and returned with a recommended list of projects.

REFURBISHMENT REPORT

Introduction

The project started with needs assessment research conducted in May 2021. The research revealed challenges and pains that learners, teachers and community members surrounding the schools faced to access safe and clean drinking water. The research was conducted in 33 schools and recommended 18 school borehole hand pumps for refurbishment.

Malawi is one of the countries that have been affected by the COVID-19 pandemic. This is a threat to schools especially those that do not have functional hand pumps. The Project introduced by African Water has come at the right time as it will help the country in fighting COVID-19 pandemic through WASH programs.

Between November 28th and December 12th, 2021, 20 schools were refurbished. Of these schools, 18 were recommended for refurbishment from the research report and two schools were only identified to be in dire need of safe and clean drinking water and required little resources to maintain their borehole hand pumps. This took the number of the borehole hand pumps worked on to 20.

The project

The first ever African Water project in Malawi refurbished 18 borehole hand pumps plus two whose pump heads were replaced with old ones removed from fully refurbished schools’ hand pumps. The purpose of the project is to provide safe and clean drinking water to learners to enhance and maintain the WASH program and reduce distances covered in search of water. This benefits learners in spending more time in classes as much as it gives a direct benefit to teachers and the surrounding communities. It has been a learning process for the Malawi team as we are coming to know the common challenges which will help us to prepare thoroughly for upcoming projects.

Supply Chain (Project Learning for Malawi)

However, a component of pumping test was not included in the project. This was because the required 3” submersible pump was not found in Malawian shops. It is our hope that in the future projects, a pump will be procured from Zambia.

Pumping test help us to find the dynamic water level and this helps to install the pumping cylinder at the right depth. In the absence of pumping test, we relied on community knowledge of borehole challenges.

Common problems

The implementation of the project identified common borehole problems that schools in Malawi face. The common problems identified are as follows:

Plungers. These are either brass or plastic, creating a common challenge with the rubber wearing out quickly. Some plunger heads break, making it difficult to be fished out and often pump menders opt to leave the broken parts resting on the foot valve and installs new one. This brings about fast wearing out of the new install as it comes in contact with the broken parts. When a pumping plunger breaks off from the connecting rod it takes expertise to fish out.

Rising main pipes. The common problem identified is that when the riser pipes develop faults by cracking the pump, menders make bend joints which bring about bend riser and crooked strokes. The zig-zag movements of rods wears out the centralizers and cup seals faster than anticipated. Some are loosely joined with little or expired solvent cement making the pipes to disjoin resulting in difficulties in pumping.

Pump heads. The main challenge is on the fulcrum pin and the bearings which wears out quickly. This is caused by either the unusual pumping styles or a large population using such water points. When the bearings break or wear out they bring about wobbling on the pumping handle which in turn rubs inside the pump head causing the fulcrum pin to rub against the fulcrum pin slot. This results into an enlarged fulcrum pin slot, a worn out fulcrum pin and a bruised inside wall of the pump head. The wearing out of plastic bush bearings at times, is caused by two people operating the pumping handle at the same time which results into pulling of the handle to the sides.

Cylinders. Many sites complained of worn out cylinders which comes about due to many years of use or frequent wearing out of the cup seal and the plunger in turn rubbing against the brass wall of the cylinder. When the rubbing goes on for some time, the cylinder wall develops a rough surface resulting into scratching of the cup seal which then fails to bring water to the surface.

Challenges faced during implementation

During the implementation of the project, the following challenges were encountered;

The suppliers identified did not supply all the items needed at once which delayed the start of the project. This led to the project starting 5 days late.

There was only one supplier of Afridev Hand Pumps in Mzuzu, creating an over reliance and a single point of failure.

Pumps were supplied without riser pipes in Malawi, meaning the team needed to buy riser pipes separately.

-

Name of School

Katete Boys Primary School

Kamatawo Primary School

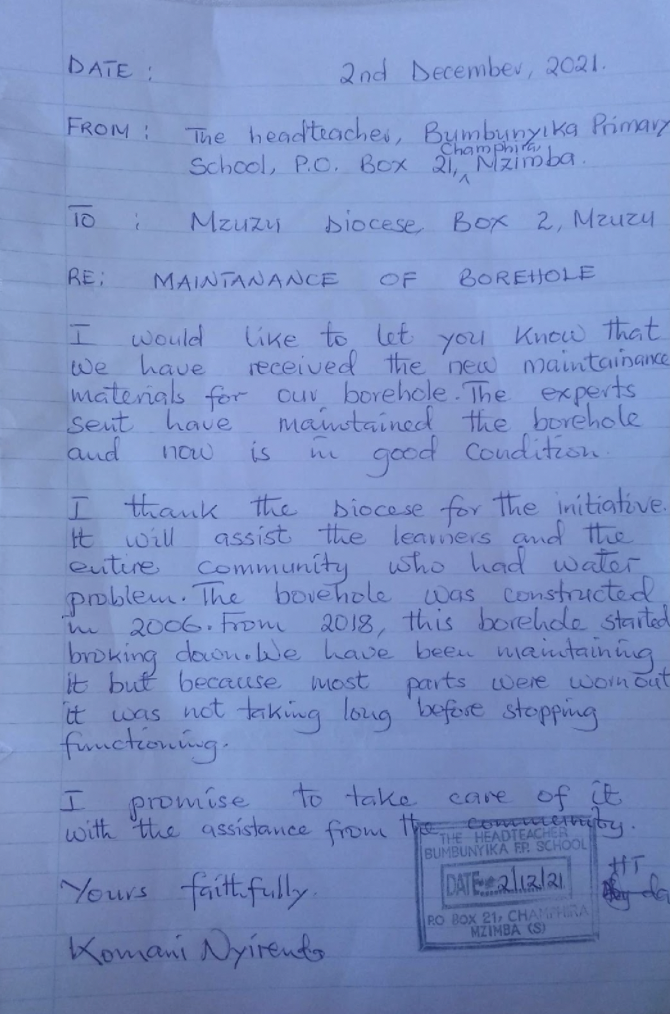

Bumbunyika Primary School

Chisambo Primary School

Mzagambuzi Primary School

Mzomzoma Primary School

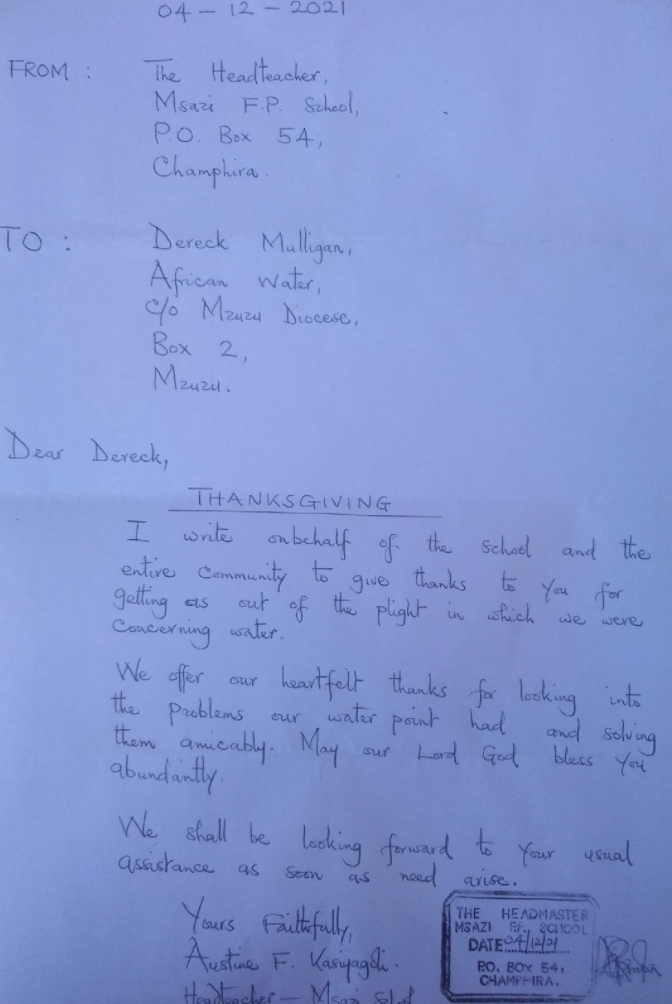

Msazi Primary School

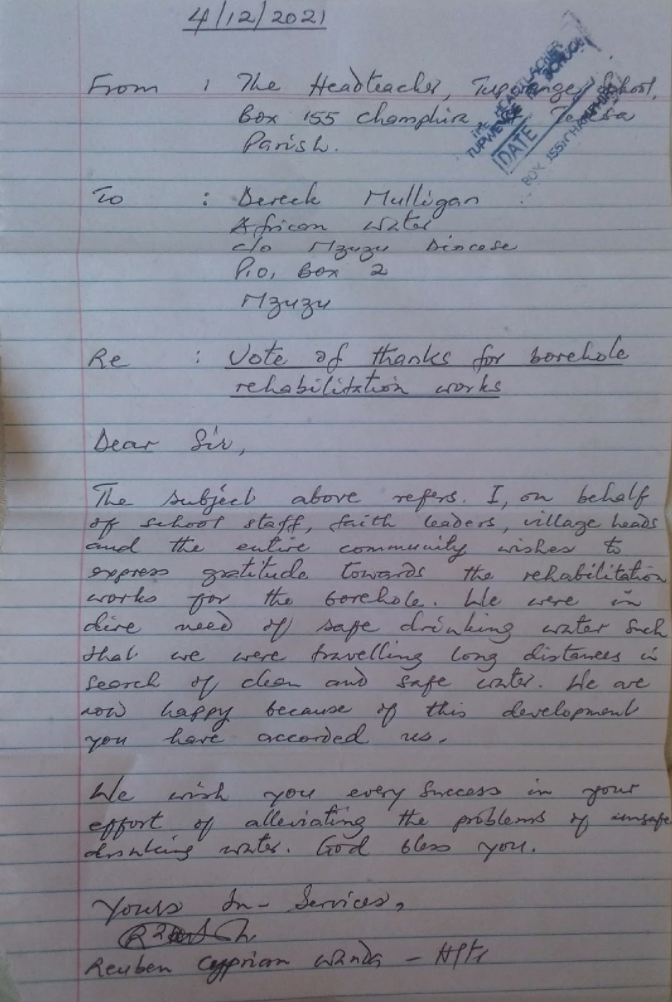

Tupwenge Primary School

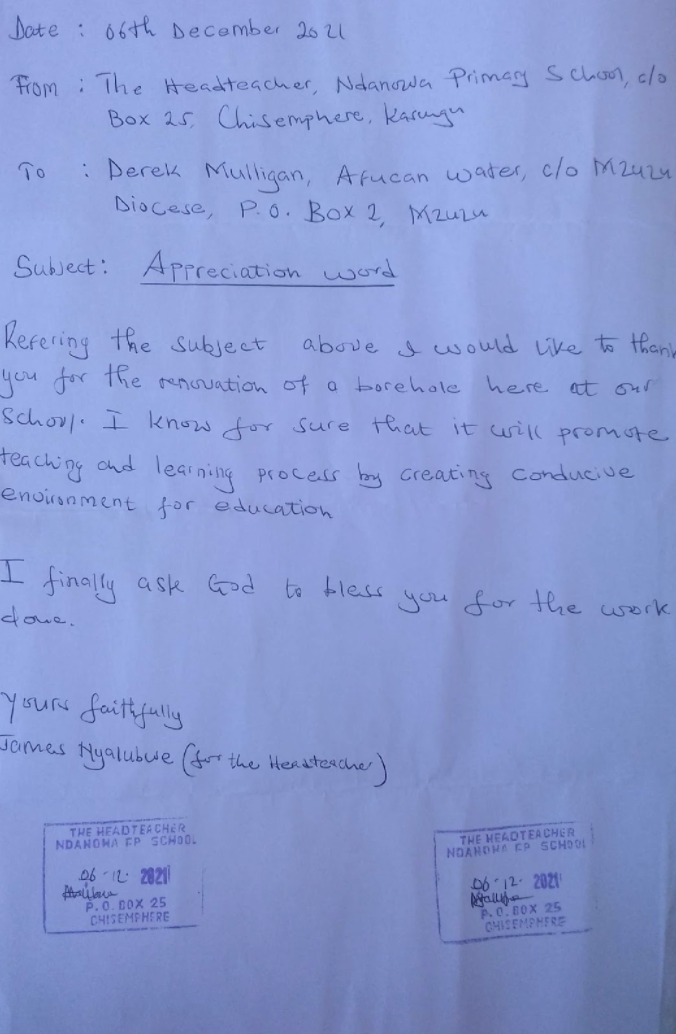

Ndanowa Primary School

Kadweya Primary School

Mthira Primary School

Nkhanga Primary School

Chanjovu Primary School

Jati Primary School

Bowe Technical School

Tigabanenge Primary School

Vazara Primary School

Chatale Primary School

-

Riser main pipes installed

10

12

11

13

11

11

12

12

12

14

11

9

10

14

12

15

14

11

-

Rods

10

12

11

13

11

11

12

12

12

14

11

9

10

14

12

15

14

11

-

Borehole depth (m)

33

33

33

47

44

49

57

45.50

42

45

36

29

47

45

41

51

46

45

-

Static water level (m)

15

12.50

15

15

14.23

11.98

10.98

12.28

26.25

17.60

25.14

15

7.71

17.69

28.10

10

19

9